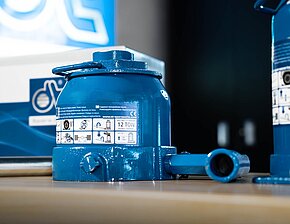

Product Portrait

Hydraulic jacks

suitable for: Mercedes-Benz, Volvo, VW etc.

In the new PS Tips video, the professional shows several variants of a jack and explains how it works, among other things. Before using a jack, however, there are a few points to bear in mind to ensure safety. Lars has summarised these in the video:

- Make the right choice: The right jack must first be selected for each vehicle in terms of load capacity.

- Level surface: It must be ensured that the jack is positioned on a stable, level surface.

- Measures on the vehicle: To avoid tension, wedges should be positioned under the wheels and the handbrake released.

- Correct attachment points: Markings (e.g. notches or crosses) can be found on DT Spare Parts jacks to ensure optimum alignment.

- Safety first: As an additional safeguard against slipping, the vehicle should be lowered onto jack stands to ensure safe working.

- Air-free system: During storage, an upright position and regular pumping should be taken into account so that no air can enter the system.

These instructions can also be found on the jack itself. For every jack from DT Spare Parts, there are also always fitting instructions and an operating rod, making the set complete. This means that the items are immediately ready for use and easy to handle.

A hydraulic system is installed in the jack from DT Spare Parts: When the adjuster is tightened, oil from the expansion tank is channelled past a ball into a pressure chamber by a vacuum generated when the rod is lifted. When the rod is pressed down, the inlet opening of the pressure chamber is closed by a ball and the pressure is channelled into the space under the piston via another ball. As a result, the piston gradually rises, as each pumping movement transports more pressure into this chamber.

To release the pressure again, the adjuster is turned anti-clockwise. The oil is then fed back to the expansion tank and the piston lowers. This can be accelerated by applying manual pressure to the piston.

The expansion tank is filled with oil, which is pressed into another chamber during the pumping process, creating a vacuum. Two integrated balls in the system alternate and ensure smooth pressure equalisation. If the vehicle is to be lowered again, the pressure screw must be loosened slightly so that pressure can escape in a controlled manner. If a malfunction occurs, the reason may be air in the system. Lars has a very special tip for this: “To solve the problem, the pressure screw is loosened slightly anti-clockwise using the operating rod supplied. Then pump several times to release the air. However, it is important to ensure that the pressure screw is only turned a maximum of two turns.”

If you have any technical questions about Diesel Technic products and services, the Parts Specialists will be happy to answer them via their HelpDesk and offer the appropriate support: helpdesk.parts-specialists.com.