Product Portrait

Condensers for air-conditioning units

Suitable for: trucks and buses

Further links

Similar articles from the product range

Note: Accessories are listed on the respective article detail page in the Partner Portal.

DT® condensers for air-conditioning units are distinguished by the following properties:

- Hight quality

- Excellent processing

- Optimum functionality

- Excellent heat conductivity

- Durability

We recommend regular maintenance of air-conditioning units.

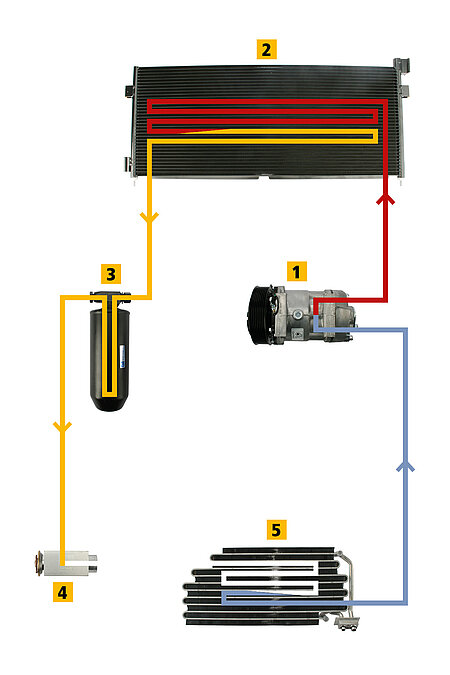

Functional description of the individual components of the air-conditioning circulation:

- Compressor

Transports the coolant through the air-conditioning system. It vacuums the coolant in a gaseous state in order to transfer it condensed under high pressure to the condenser.

- Condenser

It has the task of cooling the heated, pressurised coolant. The heat is emitted in the ambient air through cooling fins. The pressure of the coolant reduces due to cooling and the state of the aggregate changes from gaseous to liquid.

- Dryer

The dryer has the job of cleaning the coolant and extracting the moisture from it. The filter dryer only has a certain capacity for the collection of fluid. The dryer should therefore be exchanged during each repair or maintenance.

- Expansion valve

The expansion valve takes the fluid coolant from the high-pressure to the low-pressure area. It controls the injected amount of coolant using the thermal load.

- Evaporator

The pressurised coolant expands in the evaporator. It then changes from the fluid to the gaseous state. The created evaporation cold is emitted into the ambience and conducted into the interior of the vehicle using the large evaporator surface.