Product Portrait

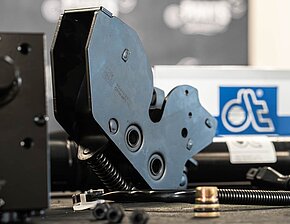

Cabin Tilt System

suitable for: Iveco, MAN, Mercedes-Benz, Renault, Scania and Volvo etc.

The DT Spare Parts range for the cabin tilting system comprises over 370 items and contains suitable spare parts for numerous brands - including Iveco, MAN, Mercedes-Benz, Renault, Scania and Volvo. The tilting hydraulic system has many different components that can be replaced. DT Spare Parts offers various repair kits, manual and electric tilt pumps, cylinders and locking devices for this purpose. In the Diesel Technic Partner Portal, customers can choose the suitable spare part from a total of more than 43,000 products.

To guarantee a continuous product quality, the Diesel Technic Quality System (DTQS) has its own test bench. The components of the cabin tilting hydraulics (e.g. tilting cylinders, tilting pumps and locking devices) from DT Spare Parts are regularly checked for functionality at a pressure up to 500 bar. Furthermore, the sealing materials are checked as a part of Diesel Technic’s comprehensive quality management, because not all elastomers are suitable for the applications with hydraulic oils.

The cabin in combination with the tilting hydraulics is a complex system, which is why special attention should be paid to certain settings, explains the Parts Specialists. When the cabin is tilted, it is signalled by an indicator lamp in the vehicle. If this is still active even though the cabin is already fully lowered again, it can be assumed that the locking device is not working properly or that the sensor or cables from the sensor to the display electrics are defect. In this case, a inspection has to be initiated immediately, as there is a risk that the cabin has not tilted back completely. The problem of sluggishness can be solved by using lubricant or replacing bent parts. In the event of an electrical malfunction, we also offer individual sensors.

Before the cabin can be tilted, all exposed objects must be removed from the cabin so that they do not cause any damage. Furthermore, there persons are not allowed under the tilted cabin and the vehicle must be secured against rolling off. In certain cases, such as previous damage to the tilting system, it is sometimes necessary to flush the hydraulic system of the tilting system in order to remove dirt and contaminants from the system.

For technical questions and assistance, the Parts Specialists from Diesel Technic are available with their HelpDesk: helpdesk.dieseltechnic.com.