Product Portrait

Belt tensioner

Suitable for: Mercedes-Benz

Further links

Similar articles from the product range of the brand DT Spare Parts

Note: Accessories are listed on the respective article detail page in the Partner Portal.

Tips & Tricks

The belt tensioner is built into the vehicle in a slightly concealed position, so space should first be created in this working area. It is important to assess what the longitudinal grooved belt of the dismantled item looks like. If the marks on the roller are offset from the centre, the belt does not align. All adjacent components as well as the bearing clearance of the air conditioning compressor and idler pulley must be checked when the belts are disassembled. A leaking hydraulic cylinder can be a sign of an excessively short belt or one-sided load.

The mounting surface should be cleaned before installing the belt tensioner. It is important to mount the mounting screws with the torque specified by the manufacturer to avoid clamps or tensions. The longitudinal grooved belt should always be replaced. Now the engine can run at idle speed and a visual check should be carried out to check whether the belt is aligned and the tension corresponds to the manufacturer‘s specifications.

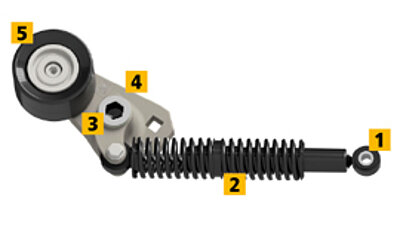

Structure of the belt tensioner

- Dampers

- Compression spring made of spring steel

- Sintered metal bushing

- Tension pulley bracket

- Tension pulley