Product Portrait

Drive belts

Suitable for: trucks and buses

DT® Spare Parts power belts are firmly connected drive belts and banded by a cover plate, so that the belts remain tear-proof, even in extreme performance situations.

Drive belts of the brand DT® Spare Parts are characterised by high power transmission, low vibration and quiet operation. This result is achieved by regular monitoring of the accuracy of the profile during production and a tight length tolerance of max. +/– 5 mm.

A long service life of DT® Spare Parts drive belts is guaranteed by the use of high-quality oil and temperature resistant materials, which prevent the belt from tearing and becoming porose, even at extreme temperatures of –40°C to +120°C.

Further links

Similar articles from the product range

Note: Accessories are listed on the respective article detail page in the Partner Portal.

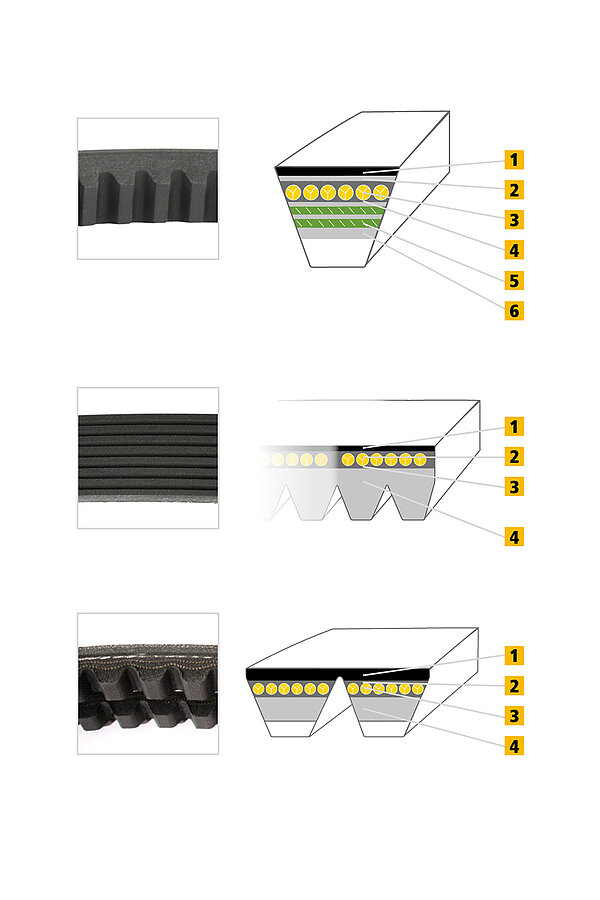

Construction of DT V-belts (AVX-profile)

- Cover plate

- Ethylene Propylene Diene rubber (EPDM) with textile fibres

- Polyester

- Adhesive-efficient Ethylene Propylene Diene rubber (EPDM)

- Mixed fibres

- Ethylene Propylene Diene rubber (EPDM)

Construction of DT multiribbed belts (PK-profile)

- Cover plate

- Polyester

- Adhesive-efficient Ethylene Propylene Diene rubber (EPDM)

- Ethylene Propylene Diene rubber (EPDM)

Construction of DT power belts

- Cover plate

- Adhesive-efficient Ethylene Propylene Diene rubber (EPDM) with textile fibre

- Polyester

- Ethylene Propylene Diene rubber (EPDM)