Product Portrait

Cooling system

suitable for: Citroen, DAF, Iveco, MAN, Mercedes-Benz, Scania, Volvo etc.

Cooling water circuit

To start the video, Lars uses an illustration to show the small and extended cooling water circuit. The small circuit comprises the water pump, engine block and heater. When the temperature reaches around 80 and 100 degrees (depending on the variant), the thermostat opens and the coolant is channelled through the radiator. This temperature is cooled down with the help of the fan and the airstream.

Thermostat

As the thermostat is the most important control element in the coolant circuit, the DT Spare Parts brand offers different variants. Lars mainly presents mechanical solutions in the video. As soon as the correct operating temperature is reached, the expansion element pushes open the valve in the thermostat and opens the large circuit. ‘When installing, it is important that the vent hole points upwards so that the valve can be vented correctly,’ explains Lars. There are thermostats with different opening temperatures, which makes control in the coolant circuit even more precise. ‘Although the items look the same, they must not be installed in the same vehicle as they have different temperature specifications,’ Lars points out. This information can be found directly on the product itself. The data is also included in the item description. In the van sector, electric versions are sometimes available that have a temperature sensor.

Water pump + repair kit

To obtain the right water pump for each vehicle and guarantee a perfect fit, the reference number can be entered in the partner portal. There you can also see whether suitable repair kits are available. Lars gives another important tip in the video: ‘During the running-in phase, the mechanical seal may initially leak slightly and drip. The coolant lubricates the seal during the running-in phase and ensures that it is tight afterwards.’

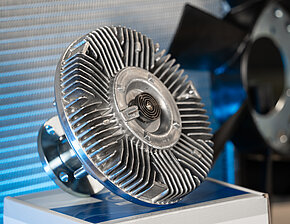

Cooler

As the name suggests, the temperature of the coolant is reduced by the radiator. The coolant is cooled by horizontal cooling pipes. The surface area is extended by fins between the cooling lines, thus optimising the cooling line. ‘It is important to ensure that there is no major contamination, otherwise effective cooling cannot take place,’ says the Parts Specialist. The PS Tips video also shows a fan that is controlled electrically. In the van, the fan is controlled purely electrically. The control unit decides whether to switch on the fan depending on the operating status.

Frequent error patterns:

The coolant plays a central role in the vehicle, not only for regulating the temperature of the engine, but also for cooling other operating fluids such as engine oil and transmission oil. Known error patterns that can occur are as follows:

- Oil cooler problems: The oil cooler is surrounded by the coolant and can corrode due to incorrect mixing ratios of water and antifreeze. As the coolant fulfils lubrication and corrosion protection functions in addition to its thermal properties, an incorrect composition can lead to leaks. This results in high repair costs.

- defective cylinder-head gasket: A damaged cylinder-head gasket can cause combustion pressure to enter the cooling system. This can lead to increased pressure in the cooling circuit and further damage.

- The compressed air area in the compressor head is also surrounded by the coolant. If pressure from the compressor enters the cooling system, the pressure rises above the intended value of approx. 1 bar. This can lead to malfunctions. The DT Spare Parts brand has discovered that there were assembly problems in the market where the centre screw of the compressor head was not fastened according to the manufacturer's specifications. For this reason, we have attached a sign to this screw stating that it must be tightened after the other screws have been tightened.

- Faults during repairs to the cooling system: After repairs to the coolant system, a careful pressure test is essential. Loose radiator hoses or incorrectly tightened screws can cause leaks. Torques should therefore be strictly adhered to and the following steps carried out: Pressure test after repair, test drive and then pressure test again.

- Selection of the correct coolant: The coolant is an essential component of the system. It is imperative to use the operating fluid prescribed by the manufacturer in accordance with the standards and specifications in order to ensure corrosion protection and optimum functionality.

If you have any technical questions about Diesel Technic products and services, the Parts Specialists will be happy to answer them via their HelpDesk and offer the appropriate support: helpdesk.parts-specialists.com. The installation instructions also provide important information on the cooling system.