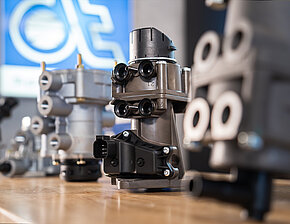

Product Portrait

Brake valves

suitable for: DAF, Iveco, MAN, Mercedes-Benz, Renault, Scania, Volvo etc.

Pneumatic braking systems are standard in commercial vehicles because they offer significant advantages over hydraulic systems. An integrated compressor continuously supplies compressed air, which is stored in pressure vessels and functions as an energy reserve. This provides a high actuating force during braking. The foot pedal is used to apply the entire amount of stored pressure to the brakes. “Small leaks in the system are automatically compensated for, leaks are less harmful to the environment than with hydraulic brakes, and there is no need for a deflation process when connecting a trailer,” explains the Parts Specialist.

The foot brake valve plays a central role in the pneumatic brake system. It has several connections for pressure inputs and outputs, which are used to precisely control the braking force. “One important function is the preliminary braking function, which ensures that the trailer is pre-braked slightly to guarantee stable general braking,” explains Niklas. In addition to its pneumatic tasks, the valve also fulfils electrical functions. An oscilloscope can be used to read the pedal travel, while a multimeter displays the output voltage corresponding to the pedal position. In addition, the system deactivates the speed control system when braking and activates the brake light circuit.

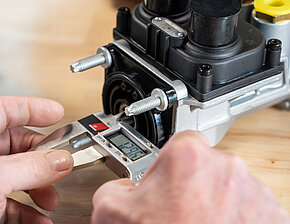

The handbrake valve is checked out in the test lab. At an input pressure of 10 bar, it's initially in the drive position, with the spring accumulators released. “When the handbrake is applied and set to the parking position, the pressure drops to zero and the spring accumulators slow down the vehicle,” Niklas shows in the PS Tip. An additional test position allows the trailer to be unlocked (trailer brake is released) in order to check the holding force of the towing vehicle. The parking brake of the towing vehicle must be able to secure the entire trailer.

The Diesel Technic Quality System (DTQS) guarantees the highest quality standards. It covers all stages of quality assurance – from development and series testing to aftersales support. With modern testing methods and ISO 9001:2015 certification, the DTQS ensures reliable spare parts and continuous product optimisation.

If you have any technical questions about Diesel Technic products and services, the Parts Specialists can be contacted via their own HelpDesk and offer the right support: helpdesk.parts-specialists.com.