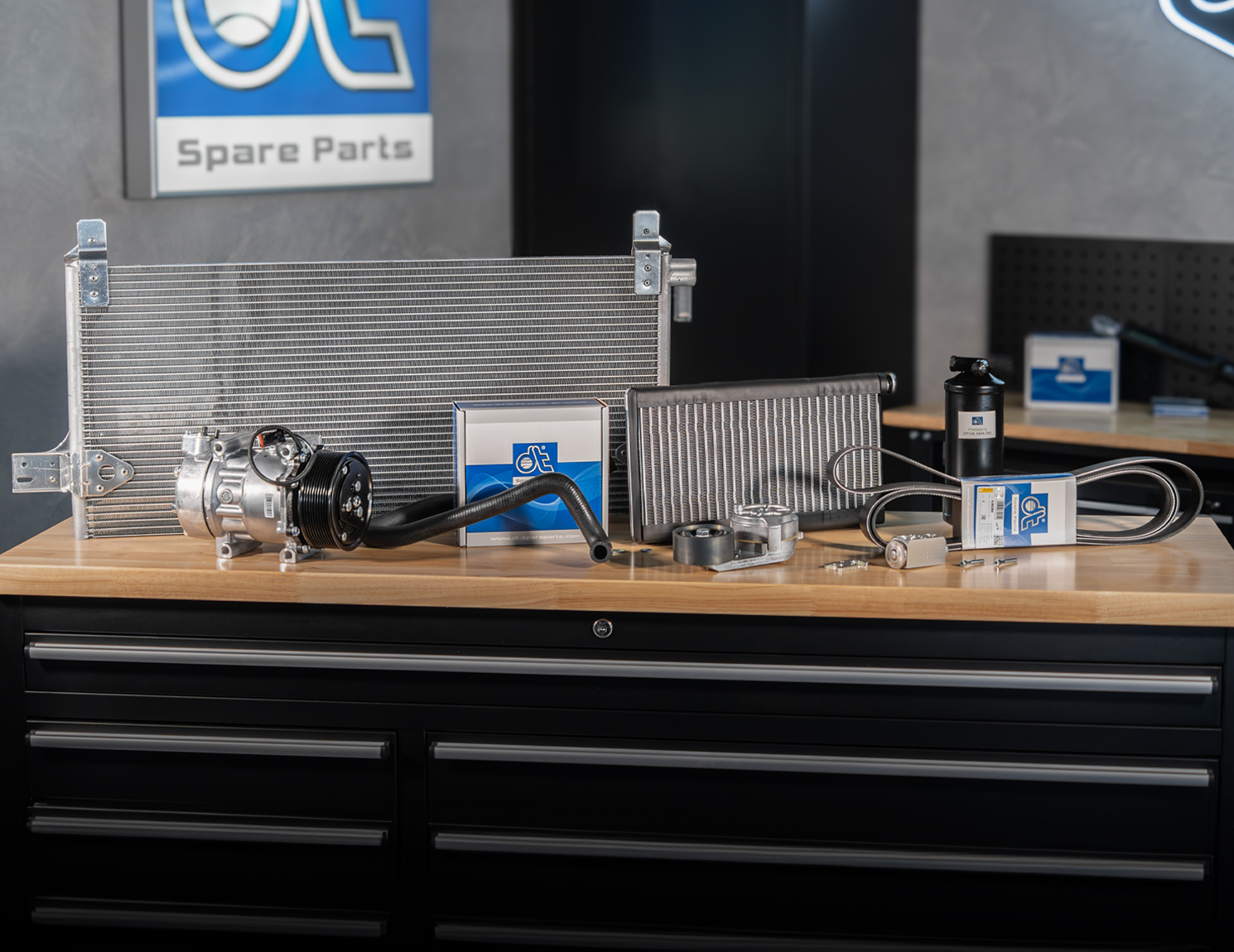

Product Portrait

Air conditioning systems

suitable for: DAF, Ford, Iveco, MAN, Mercedes-Benz, Renault, Scania, Volvo, VW etc.

On the truck, Lars demonstrates that “the energy source of the air conditioning system is the compressor, which is driven by a belt.” The compressor compresses the refrigerant and then transports the gaseous refrigerant to the condenser. This is equipped with cooling fins and condenses the refrigerant with the help of the driving air and the fan, allowing it to leave the condenser as a liquid in the direction of the dryer cartridge. Inside the dryer cartridge, the moisture is filtered out of the refrigerant using granulate, as well as other materials. This prevents corrosion and damages. The next stage is the evaporator, which is located in the interior. The liquid refrigerant is vaporised in the evaporator. Due to the resulting evaporative coolness, the passing air, which is transported by the fan, is cooled and reduces the temperatures in the cabin. Another effect is that the air in the cabin is also dried. This can for example prevent the windows from fogging up.

“When it comes to filling the system, it is important to make sure which air conditioning fluid is compatible and what quantities are required,” explains Kevin. When the system is refilled, a contrast fluid should be added to make it easier to identify any leaks in the system. This can be easily recognised with the help of black light. Different air conditioning products may never be mixed together. “A regular air conditioning service is recommended every two years,” explains Kevin. In the event of malfunctions, a workshop should be visited immediately, as the refrigerant is hazardous to the environment. A common problem can be that external particles in the system may damage the internal components of the compressor, causing it to block. “These external particles, which multiply inside the compressor due to the defect, also reach the other components via the pipes and can also cause damage there,” reports Parts Specialist Lars. In such cases, some components have to be replaced. Please also refer to the vehicle manufacturer's information. Afterwards, the system must be flushed. In some cases, several flushing processes are necessary to remove all external particles from the system. If these steps are not taken, high follow-up costs may be generated.

Kevin points out that “when replacing compressors, pay attention to the overpressure.” Before removing the blind plug, make sure that no dirt or moisture can get into the system. The article should be installed as soon as possible after removing the blind plugs. A practical tip for servicing the air conditioning compressors in winter is to run them regularly to ensure correct lubrication and extend their lifetime.

Our Parts Specialists have one last tip for the summer: stay cool, no matter where you are travelling to!

If you have any technical questions, the Parts Specialists will support you with their HelpDesk: https://www.parts-specialists.com/en/helpdesk/.

The articles from DT Spare Parts fulfil the highest industry standards and guarantee a long lifetime. Continuous and systematic testing ensures that the product quality always remains at a high level. As part of the Diesel Technic Quality System (DTQS), all products are tested thoroughly. In addition, the DT Spare Parts brand offers a 24-month brand warranty on the complete range.