Product Portrait

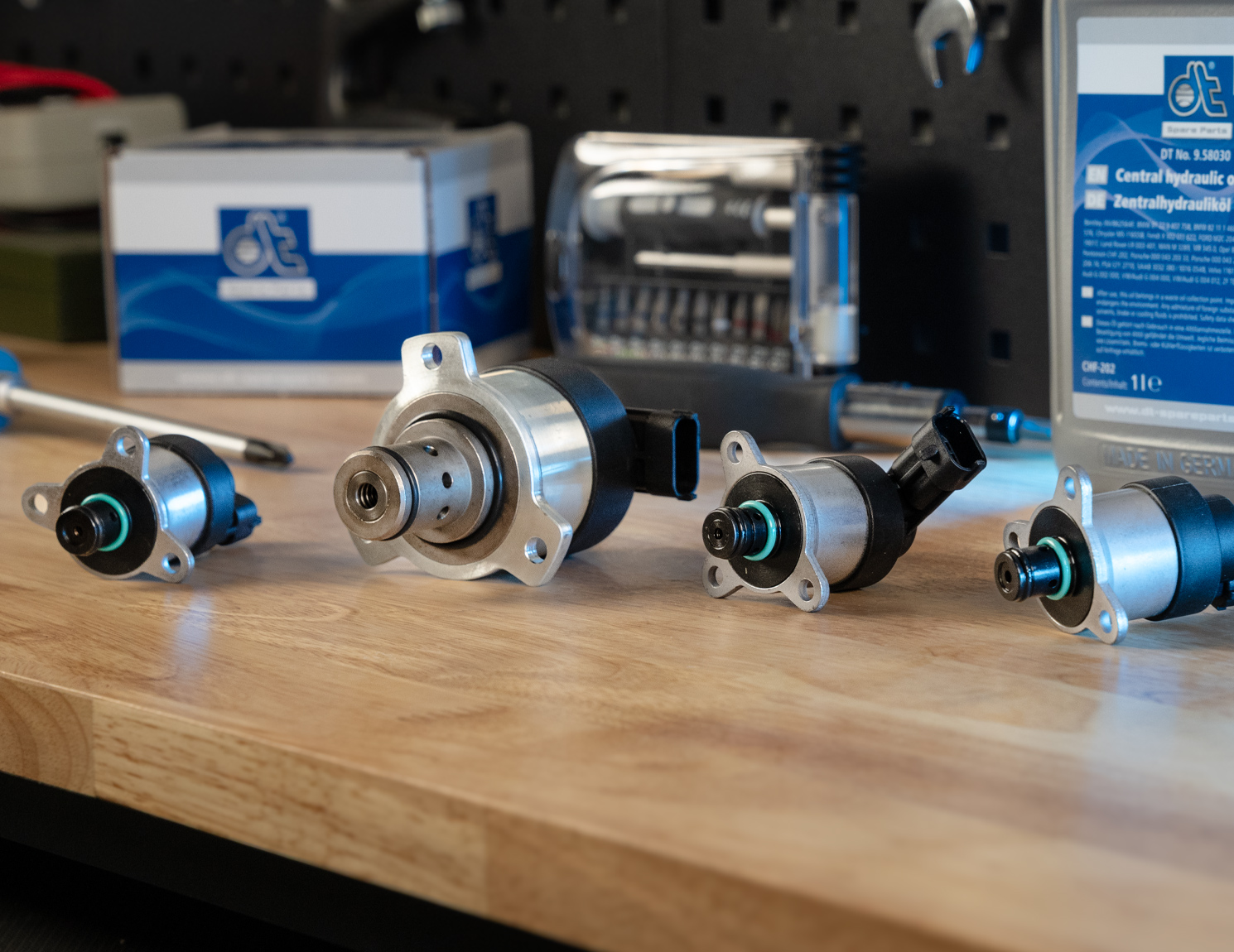

Control valves for fuel pumps

suitable for: DAF, Fiat, Iveco, MAN, Mercedes-Benz, Nissan, Volvo etc.

Niklas uses a detailed view of a valve to explain how it works and how it is constructed. “The holes in the valve itself ensure that the fuel runs through it,” explains the Parts Specialist. The fine holes also fulfil another important function. “As there is a high pressure in the valve, a correspondingly high current flow through the integrated solenoid coil is required to switch the valve. This causes the valve to heat up significantly. The holes, through the solenoid valve armature, ensure that the fuel cools the coil and avoids overheating,” comments Niklas in the video.

Through precise control of the injection pressure, a better combustion is ensured and maximum engine performance is guaranteed. This precision also leads to reduced fuel consumption. In addition, the injection nozzles or injectors and other system components are protected from overloading.

Clean fuel and regular replacement of the fuel filter are essential to prevent deposits and ensure a long service life. At the end of the video, Niklas gives another tip: “If the vehicle does not start even though the battery voltage has been checked, a defective pressure control valve may be the cause. A check using an ohmmeter or acoustic test will tell you whether the valve is still working correctly.”

Parts Specialist Niklas has collected some more hints and tips with his colleagues to make the application even easier:

- Check injector failure: If an injector failure or malfunction is suspected, the individual fuel lines are often disconnected while the engine is running in order to identify the faulty parts. This should not be carried out with high-pressure lines (e.g. CR), as damage to other components or even personal injury is possible – generally speaking, this is not a safe test method.

- Inflammation: Diesel fuel is more difficult to ignite than petrol, for example. Nevertheless, it can burn at high temperatures and with a high degree of distribution. Therefore, when working on the system, pay attention to surrounding ignition sources and disconnect the battery terminals.

- Starting the engine: If the engine does not start automatically and/or the ignition of the engine remains completely off, the cut-off valve of the pressure pump and the fuse should be checked.

- Service life: If the engine stutters when starting after standing for a while, this may be due to problems with the pre-glow system, clogged filters or leaks in the system. In some cases, air can get into the system. This may also cause the fuel to run back into the tank.

- Check the pressure control valve: If a defect is suspected in the pressure control valve, the plug connections should always be tested for voltage. It is also advisable to check the contacts for corrosion and clamping effect. With the motor switched off, the resistance at the solenoid coil can be measured; this should be very low. If the resistance is high or there is no continuity, the valve is defective and must be replaced.

- Solenoid coil insulation: The solenoid coil insulation should be checked against the housing. There should be no continuity there if a two-contact plug is used and the housing is not used as an earth conductor due to its design. (Multi-contact plugs usually indicate separate earth lines).

- Valve movement: If you hold a hand on the valve during actuation, you can usually feel the movement of the armature inside.

- Diesel quality: Regular filter changes and emptying of the water separators are important, as diesel has no cleaning properties and the quality can vary.

If you have any technical questions about Diesel Technic products and services, the Parts Specialists are available via their own HelpDesk and offer the right support: helpdesk.parts-specialists.com.