Product Portrait

Level sensor of the urea system

suitable for: DAF, Ford, Iveco, MAN, Mercedes-Benz, SAF, Scania, VW etc.

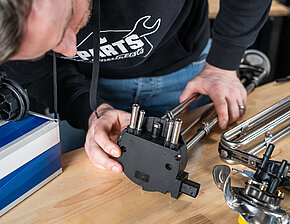

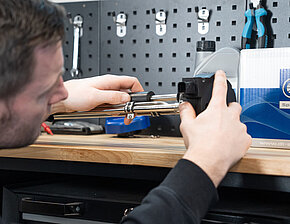

The level sensor measures the level of urea via a float mechanism. Depending on the position of the float, a corresponding electrical signal is transmitted to the control unit – the basis for the correct indication on the driver's display. “The changing resistance level can be measured directly using a multimeter, as it changes depending on the amount of urea,” explains Lars in the video.

When looking at the level sensors, the typical spiral design stands out. This is used to actively heat the urea – an essential aspect, as it freezes at temperatures as low as minus 11 °C. This means that the freezing point is lower than for fuel. The spiral accelerates the defrosting process and protects the system at low temperatures. “In other variants without a spiral, an integrated temperature sensor takes over the monitoring,” demonstrates the Parts Specialist. If the temperature falls below a certain level, the control unit activates external heating elements for anti-freeze protection.

Other components that belong to the level sensor are filter units in different variants. Line filters, for example, are used to prevent even minimal contamination from entering the system. A known error pattern here is a clogged filter, which impairs the flow rate. This may be caused by crystallised AdBlue, which reacts with air. In addition to filter contamination, the system must then be checked for leaks. “Regular filter replacement at the appropriate maintenance intervals makes it necessary to recognise defects at an early stage,” emphasises Lars.

Further accessories such as dosing modules, urea tanks and filler caps are also available from the DT Spare Parts brand. “The blue tank cap is also a clear visual identification feature for AdBlue, which can prevent incorrect filling,” explains the Parts Specialist.

If you have any technical questions about Diesel Technic products and services, the Parts Specialists are available via their HelpDesk and offer the best support: helpdesk.parts-specialists.com. In order to be able to answer requests in an even more targeted way and localise errors, it is important to always include the readout error code.