Product Portrait

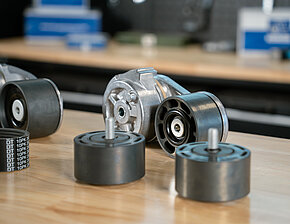

Belt tensioner (kits)

suitable for: DAF, Fiat, Ford, Iveco, MAN, Mercedes-Benz, Opel, Scania, Sinotruck, Volvo etc.

The belt runs over a pulley with an integrated ball bearing, and the housing contains a strong metal spring that has been specially designed by the manufacturer to match the belt drive and the forces required. The spring compensates for vibrations and movements of the belt and ensures a balance between power transmission and flexibility, even with increasing wear and heavy load changes. The belt tensioner is “anchored” in the engine via locking points. This means that the basic alignment is specified by the manufacturer. The tensioning arm can be operated with the appropriate tool to remove and fit the belt. It can be seen that it returns automatically – manual adjustment is not necessary, the correct tension is immediately achieved, which saves time and eliminates the potential for errors during installation.

“Before changing the belt, it is important to document the belt guide – ideally with a sketch or a photo,” explains Niklas. The reason: correct belt guidance is crucial for the functioning of the entire belt drive. If the belt is installed incorrectly, loads cannot work properly, which leads to damage or breakdowns. In addition, the profile of the belt should be checked for damage, run-in marks or cracks. Older belts may make noise after reinstallation if the belt is installed in the opposite direction to its previous running direction. In this case, it is also advisable to note the direction of rotation on the belt before removal (e.g. with a wax crayon or white paint marker). If there are several belts in the system, it is also helpful to briefly mark the driven loads on the belt. It is also recommended to check all bearings for abnormal noises or excessive play each time the belt is replaced. Deflection and tension rollers must also be checked to ensure that the bearings are clean and running without noise. The parallelism of the bearings is also crucial, as incorrect positioning can cause the belt to be thrown off.

When installing new components (deflection pulleys, light machines, etc.), it is also important to ensure that all pulleys driven by a belt are aligned axially on the same plane. V-belts and flat belts can compensate for minor misalignments, but if the parts do not match the motor type exactly, dimensional differences can exceed this limit and lead to excessive wear or constant belt slippage.

In addition to automatic belt tensioners, there are also manual versions. ‘Here, the tension is adjusted via an adjustable tension roller or even via accessory loads such as the alternator," Niklas demonstrates on the vehicle. In the example shown, the tension can be varied by turning the threaded rod. As a guideline, the belt should be able to be pressed down by 1 to 2 cm at the longest exposed point; a 90-degree turn with a little force is also a good indicator. It is important not to over-tighten the belt so as not to put unnecessary strain on the bearings.

Error patterns usually manifest themselves through noises or the smell of hot rubber. This smell occurs when the belt slips – the resulting heat causes the belt material to burn or char. Under normal conditions, bearings run almost silently. Problems can be caused by bearings being washed out due to contamination, external damage and thermal overload. In such cases, it is not necessary to replace the entire belt tensioner – the rollers are available individually from DT Spare Parts. During installation, the specified tightening torques and the use of a screw lock must be observed, as screws can loosen due to vibrations. If the noise “moves” audibly between the load-bearing components, there is usually a problem with the belt or belt tensioner. If the noise is static but the cause cannot be directly determined, it is advisable to use a ratchet extension, long screwdriver or hose. The source of the noise can be gradually located by placing the tool on the individual consumers," demonstrates Parts Specialist Niklas.

If you have any technical questions about Diesel Technic products and services, the Parts Specialists can be contacted via their own HelpDesk and offer the right support: helpdesk.parts-specialists.com.